Toshiba’s medium voltage JK Solid State Starter series offers advanced control and protection for demanding industrial applications. Engineered with soft start and stop capabilities, it provides smooth acceleration and deceleration, reducing mechanical stress on equipment. With a high current capacity rated at 500% for up to 60 seconds and true thermal modeling, these starters are built to handle challenging conditions. Their adaptable design allows seamless integration as standalone starters or within control center lineups. Utilized with Toshiba’s HVK/VK switchgear, JK starters are ideal for controlling induction, wound rotor, or synchronous motors, as well as transformers, and capacitors.

- Products

- Controls

- Medium Voltage Controllers

- JK Solid State Starter

Overview

Specifications

Download Center

Training

Overview

Versatile

Designed for use as a starter for various motor types (induction, wound rotor, synchronous).

Unique Vertical Magnetic Arc Dispersion System

Prolong the starter’s lifespan, reduces maintenance needs, and enhances safety by effectively managing arc energy.

Robust Design

Compact design reduces the installation footprint, while the rigid 11-gauge steel frame enhances durability and robust protection for the internal components, increasing efficiency and reliability in various applications.

Visible, Bolted Pressure Isolation Switch

Offers less resistance and wear on the starter, eliminating insertion pressure, and features a mechanical interlocking system enhancing safety and reliability.

Front Accessibility

Simplifies installation and maintenance by providing front accessibility to the motor connection points and the main bus.

Isolated Low Voltage Door & Swing-Out Sub Panel

Features a steel barrier for protection against accidental contact, with main bus access through a hinged sub-panel. This barrier opens to fully expose the main horizontal and vertical busing, enabling inspection or connection to adjacent cubicles without requiring rear access.

Contactors Assembled and Tested by Toshiba

Latched-type contactors are available for simplified control and reduced power consumption. High-quality vacuum contactors for reliable performance are included.

User-Friendly Interface

7” color touchscreen centralizes control and simplifies setup, configuration, and real-time monitoring with plain text interaction in multiple languages. Users can easily navigate menus, adjust settings, and monitor motor performance from a single, intuitive interface.

SSS TOOL Windows®-Based Software

Enables easy programming, startup, and troubleshooting via RS485 while also reducing startup time and facilitating data backup and email. Key features include visual programming, trend recording, multi-drop network support, and automatic software updates.

Safety Measures

Features a fiber optically isolated low voltage compartment, safety interlocking, and a non-load-break disconnect switch. It also includes a line isolation vacuum contactor and visible grounding bar for secure operation and maintenance.

Advanced System Protection

Common system protection features found in standalone motor protection relays are standard, allowing users to customize protection levels by setting warning thresholds, separating trip curves for start and run modes, utilizing a learned overload curve, or activating remote/automatic overload reset options.

Maximum Motor Protection

Includes thermally biased, programmable RTD inputs for precision thermal management, allowing for customizable alarms and trips based on temperature setpoints, all monitored remotely. The real-time clock with features like Coast Down/Back Spin Lockout and Elapsed Time Meter enhances maintenance scheduling and fault recording, while an optional Zero Sequence Ground Fault protection offers advanced safety against damage from faulty conductors or motor windings.

Fully-Rated Bypass Contactor

Increases thermal capacity by bypassing the soft starter once the motor reaches full speed, reducing heat and energy losses, enhancing efficiency, and offering optional across-the-line start.

Simplified Maintenance

Streamlined, space-saving design, with components arranged efficiently and without internal power cables.

Insulated Bearings

Extended Horsepower Capability

Insulation with Wide Thermal Capability

Low Vibration

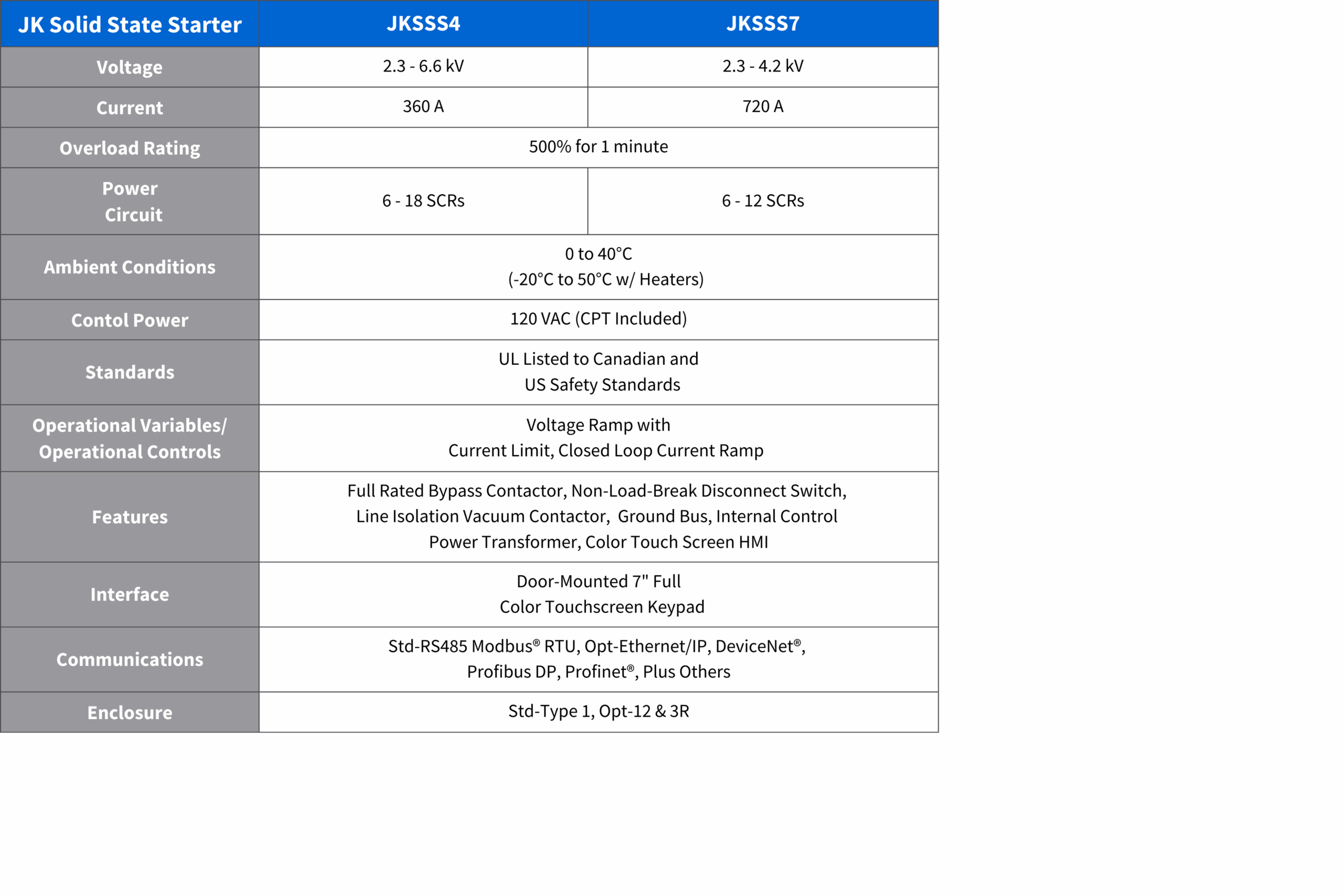

Specifications

Lorem ipsum is placeholder text commonly used in the graphic

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

Download Center

Catalog

DATA PACKAGES

Brochures

Manuals

technical References

Drawing

SOftware

Catalog

I am tab 1 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

DATA PACKAGES

Brochures

Manuals

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

technical References

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Drawing

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

SOftware

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Training

[related_post_acf]