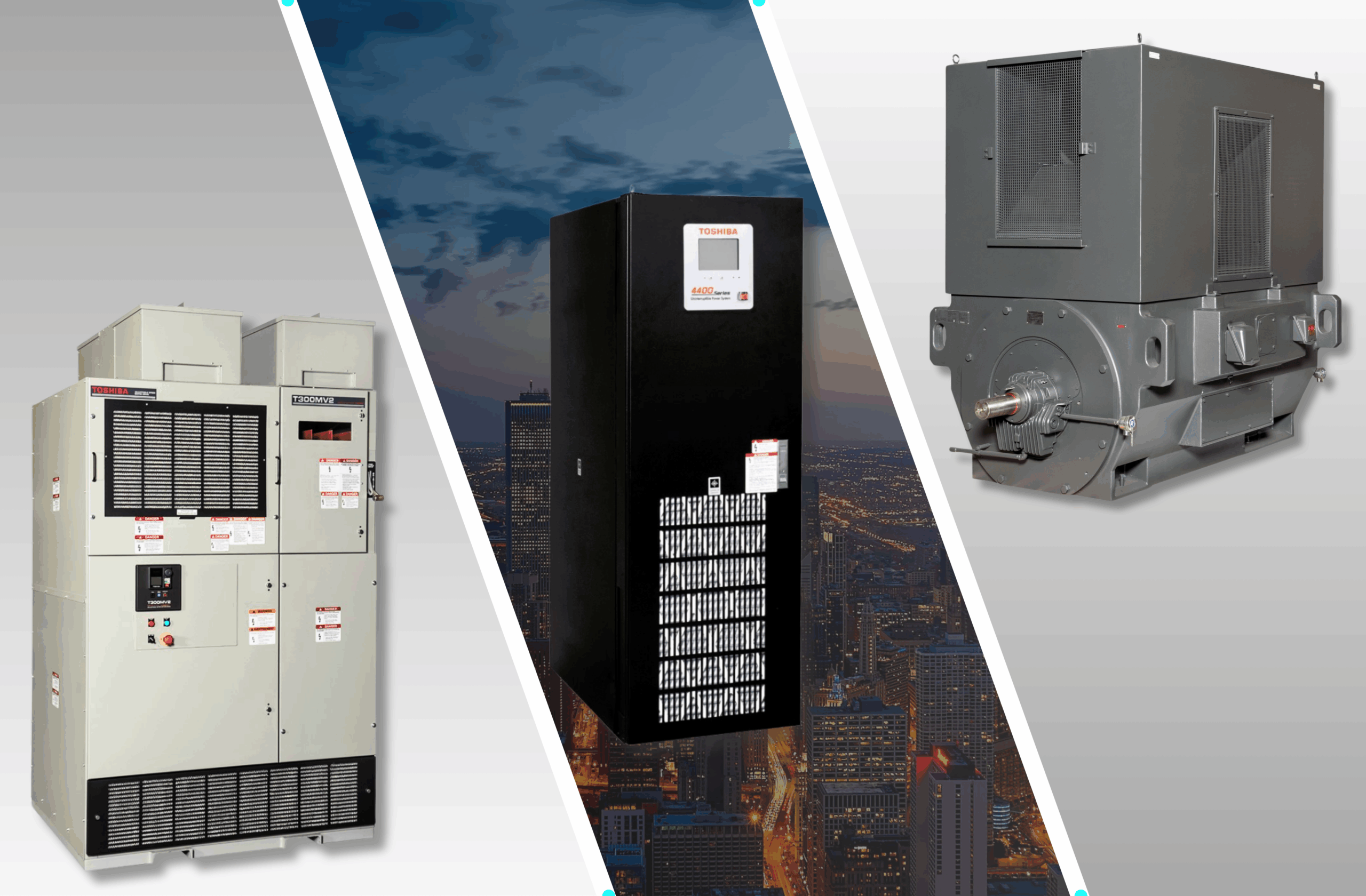

Toshiba’s medium voltage JK Full Voltage Controller series features a streamlined, space-saving design. Full-voltage starters use no internal power cables, enhancing safety and simplifying maintenance. Expanded capabilities allow for flexible configurations, whether used as an individual starter or in a control center lineup with incoming disconnect switches. Additionally, the JK Series integrates seamlessly with Toshiba’s HVK switchgear.

- Products

- Controls

- Medium Voltage Controllers

- JK Full Voltage Controller

Overview

Specifications

Download Center

Training

Overview

Versatile

Designed for use as a starter for various motor types (induction, wound rotor, synchronous) or as a controller for transformers or capacitor switching.

Unique Vertical Magnetic Arc Dispersion System

Prolong the starter’s lifespan, reduces maintenance needs, and enhances safety by effectively managing arc energy.

Robust Design

Compact design reduces the installation footprint, while the rigid 11-gauge steel frame enhances durability and robust protection for the internal components, increasing efficiency and reliability in various applications.

Visible, Bolted Pressure Isolation Switch

Offers less resistance and wear on the starter, eliminating insertion pressure, and features a mechanical interlocking system enhancing safety and reliability.

Front Accessibility

Simplifies installation and maintenance by providing front accessibility to the motor connection points and the main bus.

Isolated Low Voltage Door & Swing-Out Sub Panel

Features a steel barrier for protection against accidental contact, with main bus access through a hinged sub-panel. This barrier opens to fully expose the main horizontal and vertical busing, enabling inspection or connection to adjacent cubicles without requiring rear access.

Contactors Assembled & Tested by Toshiba

High-quality non-latched and latched-type contactors are available for simplified control and reduced power consumption.

Insulated Bearings

Extended Horsepower Capability

Insulation with Wide Thermal Capability

Low Vibration

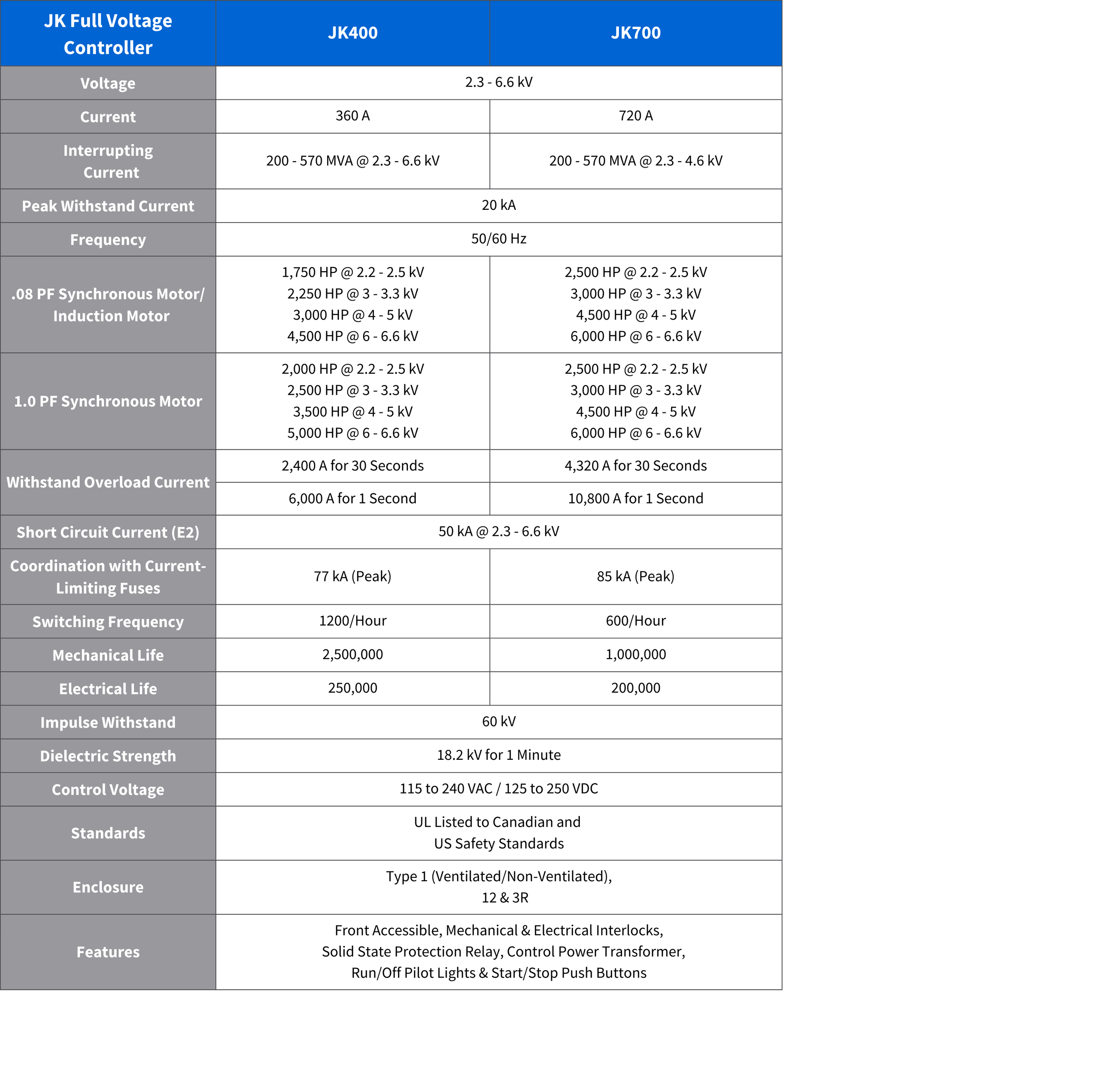

Specifications

Lorem ipsum is placeholder text commonly used in the graphic

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

Download Center

Catalog

DATA PACKAGES

Brochures

Manuals

technical References

Drawing

SOftware

Catalog

I am tab 1 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

DATA PACKAGES

Brochures

Manuals

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

technical References

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Drawing

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

SOftware

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Training

[related_post_acf]