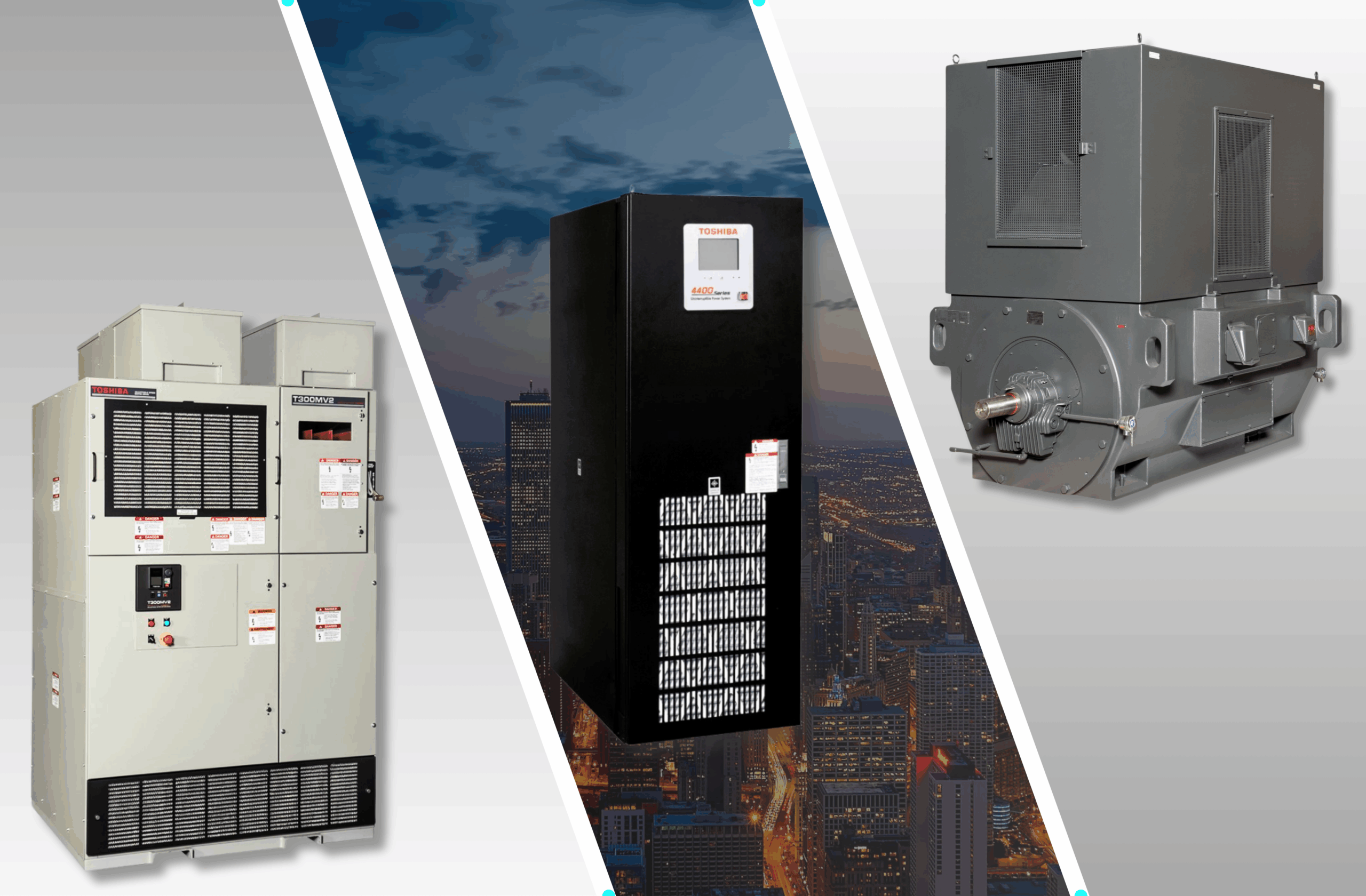

Toshiba’s Totally Enclosed Water-to-Air Cooled (TEWAC) motors are designed to meet the industry’s increasing demands for energy conservation and exceptional product performance. The efficient water-to-air or glycol-to-air cooling system enhances heat dissipation, allowing for higher output within a compact frame size. The fully enclosed design safeguards against contaminants such as dust, moisture, and corrosive elements. Whether for oil and gas exploration, chemical processing plant, or other industrial applications, TEWAC motors can be tailored to meet specific application requirements made possible by Toshiba’s in-house design, engineering, and manufacturing capabilities.

- Products

- Medium Voltage Totally Enclosed

- Motors

- Totally Enclosed Water-to-Air Cooled

Search by Rating

Overview

Specifications

Download Center

Training

Overview

Compact Design

Enhanced cooling efficiency enables these motors to be smaller and lighter, reducing the need for large heat sinks and extensive ventilation systems.

Ingress Protection

The IP55 robust design effectively prevents the ingress of humidity, dust, dirt, and other environmental contaminants, providing reliable operation even in challenging conditions.

Thermal Protection

Embedded 100 Ω platinum stator RTDs, two per phase terminated in an auxiliary box, help protect the motor’s insulation system from excessive heat and unsafe operation.

Humidity Protection

120V space heater is included in all frames.

Vibration Provisions

Designed for mounting vibration sensors (1/4” NPT) on each bearing bracket.

Drive Duty Compatibility

The insulation meets NEMA MG1 Part 31 standards. It can be paired with a UL-Listed Medium Voltage Drive, which features a motor-friendly multiphase neutral point clamped output.

Rotor Options:

Aluminum Rotor

High-pressure diecast aluminum rotors offer a lightweight, cost-effective solution. Low rotor inertia improves acceleration and deceleration, while excellent thermal conductivity enhances cooling. Corrosion-resistant properties increase reliability in harsh environments.

Copper Bar Rotor

Copper bar rotors deliver high electrical conductivity for improved efficiency and reduced losses. They provide higher starting torque and operate at lower temperatures, making them ideal for heavy-duty, high-performance applications where thermal stability and energy efficiency are critical.

Insulated Bearings

Extended Horsepower Capability

Insulation with Wide Thermal Capability

Low Vibration

Specifications

Lorem ipsum is placeholder text commonly used in the graphic

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

Download Center

Catalog

DATA PACKAGES

Brochures

Manuals

technical References

Drawing

SOftware

Catalog

I am tab 1 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

DATA PACKAGES

Brochures

Manuals

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

technical References

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Drawing

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

SOftware

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Training

[related_post_acf]